FROM WASTE TO LIFE

Mycelial Skin in Bio-Digital Fabrication: Hybrid Pathways for Upcycling Fired Clay

2025

From Waste to Life is my Final Master Project that extended from my last project Arts of Living Aesthetics, where I explore the potential value from living beings for contributing to the circular material system.

This project proposes a novel route for upcycling fired ceramic waste by leveraging the surface-binding and structural properties of “mycelial skin”—a thin, biologically active fungal layer that forms at the interface between substrate and environment.

It combines parametric clay printing, recycled ceramic additives, and fungal cultivation to explore how Ganoderma lucidum can colonize and reinforce 3D-printed clay bodies containing up to 35% fired ceramic waste.

It aims to articulate new hybrid material pathways, where digital tools and living systems collaboratively reconfigure waste into possibility.

The project also investigates the potential of mycelium recycled clay composites as speculative design materials that rethink matter, waste, and living collaboration. Using a Material-Driven Design (MDD) methodology, explores how microbial life can actively shape material behavior. A series of handmade and 3D-printed prototypes, combining interaction, tactile exploration, and growth observation—demonstrate how mycelium transforms recycled clay substrates, both structurally and experientially. By evaluating tactile qualities alongside mechanical properties, the research reveals new material affordances and points toward the development of circular and co- evolving material systems that integrate living processes into design.

* The project was started as a final master project at Industrial Design program at Eindhoven University of Technology (Supervisor: Bahareh Barati)

Publication

"Mycelial Skin in Bio-Digital Fabrication: Hybrid Pathways for Upcycling Fired Clay.” In Mycology for Architecture, edited by Dilan Ozkan. Forthcoming, 2026.

Report

Report M22 Final Report_Fengyuan_Exploring Bio-Affordances in Mycelium Clay Composite for Circular Material

Workflow

Fragment

Break down fired ceramic waste into smaller hards

Clay-mycelium hybrid forms

Resulting bio-hybrid material or designed objects

Mill

Grind fragments into power

Growth Phase

Observe colonization, skin formation, and surface interaction

Sieve/ Fine powder

Sift to obtain uniform particle size

Mix/ Paste Preparation

Add virgin clay, organic addtives, and water to form a printable paste

Inocuate & Cultivate

Introduce fungal mycelium and maintain controlled growth conditions

Forming

Shape the paste through hand-forming or 3D printing

Sterilize (Autoclave)

Sterilize printed objects to prepare for inoculation

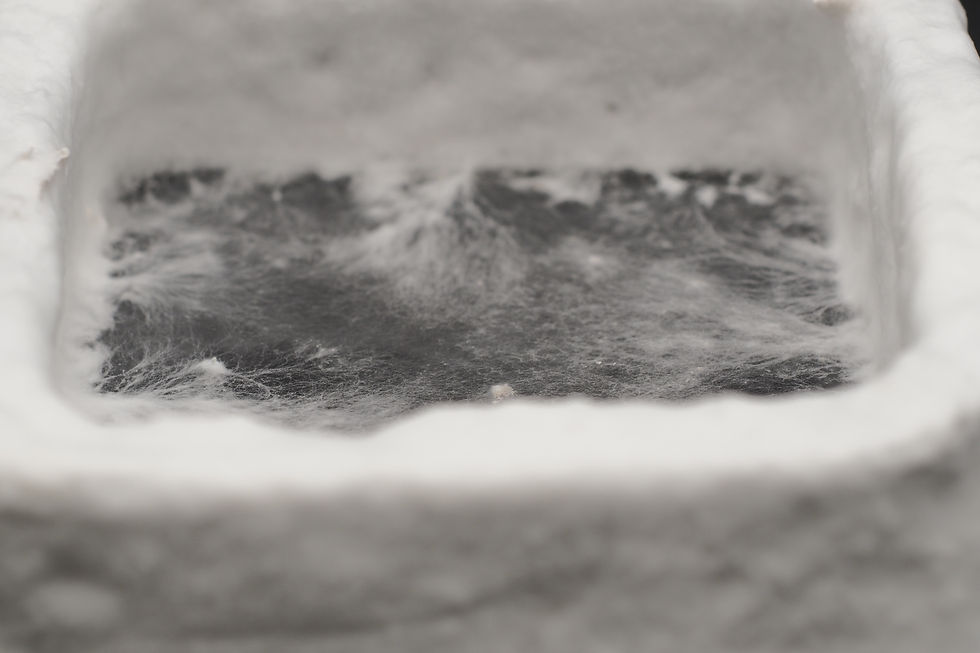

Bridging Behavior of the Mycelial Skin

L: 3D-printed sample with hand-carved rhombic perforations.

M: Sample after 8 days of incubation, showing complete bridging of the holes by mycelial skin.

R: Translucency of the dried mycelial skin revealed when held against backlight.

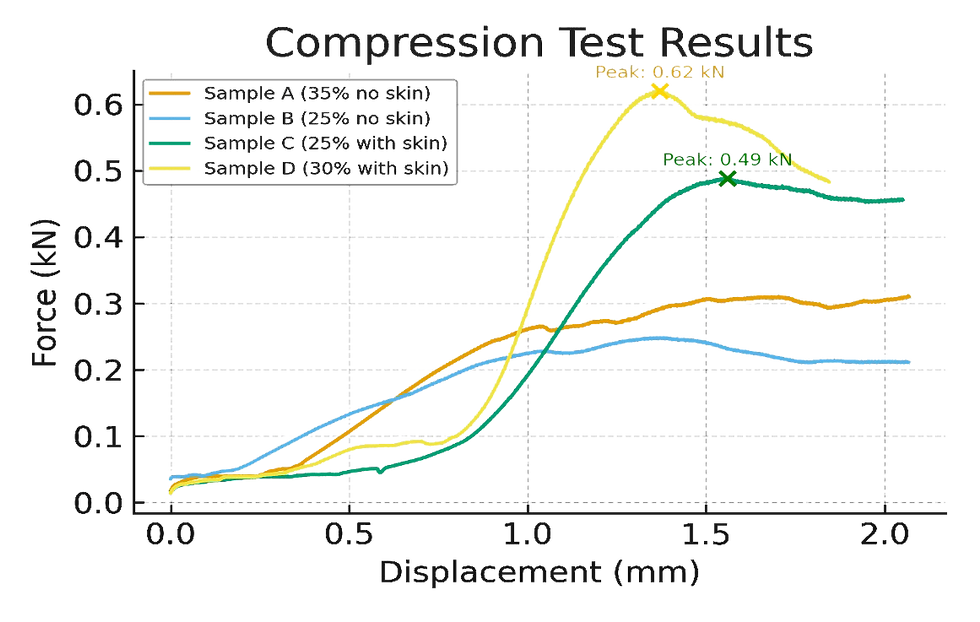

Compression Test

Compression test setup and results for recycled clay composites with and without mycelial skin.

L: Sample D positioned in the Instron hydraulic universal testing machine.

R: Post-test condition of Sample B (uncolonized) and Sample D (with thick mycelial skin).

Sample A

35% fired clay without mycelium

Sample B

25% fired clay without mycelium

Sample C

25% fired clay with mycelial skin

Sample D

30% fired clay with thikcer skin

Graph of compression test results, demonstrating a two-fold increase in compressive strength for samples encased in mycelial skin compared to their uncolonized counterparts.

Parametric Design to 3D Printing and Hybrid Product